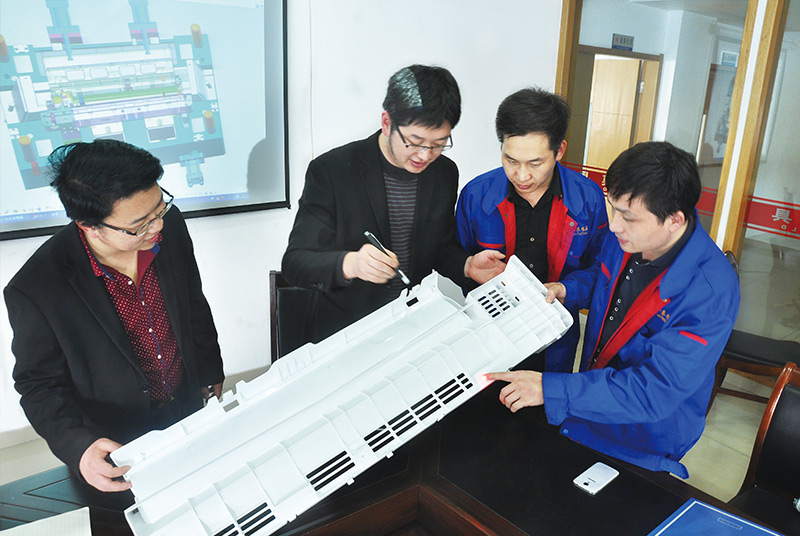

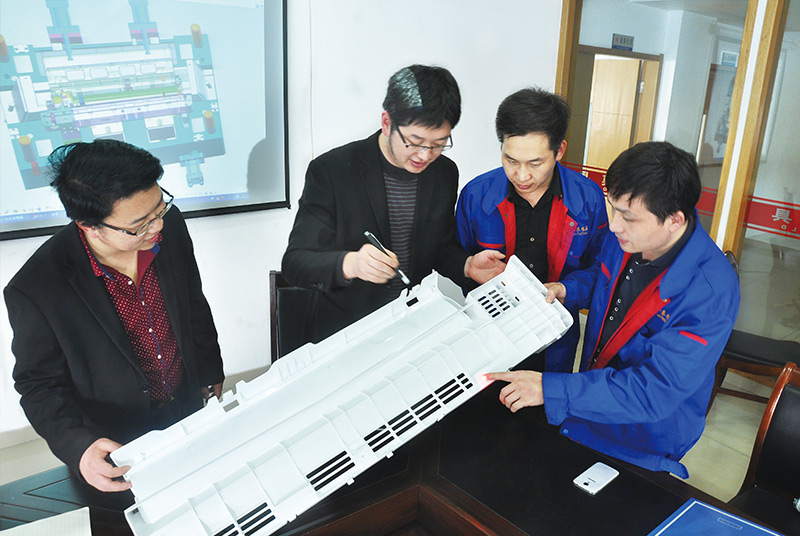

Mould Design

Meticulous pursuit of detail.

Meticulous pursuit of detail.

Lean production keep up with the times, Exquisite source in details, Details create success.

Kun Tai has advanced workshop management and modern production equipment, the production process strictly implement the 6S management and ISO9001 quality system.

Advanced equipment is the cornerstone of quality products production, Kuntai constantly pay attention to production equipment industry leading, and constantly introduce advanced production and processing equipment. In order to provide comprehensive and efficient service, the company has introduced the advanced technology and management philosophy, in order to achieve the from the mold design, processing, testing to test mode, a series of service, greatly reducing the customer's new product development cycle. Over the years we have maintained stability and competitiveness of the products, to create benefits for customers.

| N0. | Equipment Name | Table size | brand | Quantity |

| 1 | Five axis precision machining center | 3500*2500 | HISION | 1 |

| 2 | Gantry precision machining center | 3200*1750 | HISION | 1 |

| 3 | Gantry machining center | 2200*1000 2100*1000 |

DAHLIH | 2 |

| 4 | Precision machining center | 1600*1200 1600*1300 1500*770 1200*800 1200*450 1100*450 |

QUICKJET HISION |

9 |

| 5 | Electrical discharge machine | 1500*700 1500*770 1000*800 700*450 650*500 640*400 600*500 500*320 |

HAIEN DIMENG AGIECHARMILLES OMIRON |

11 |

| 6 | Deep hole drill machine | 2000*1200 | WIM | 1 |

| 8 | Coordinate measuring machine | 2000*900 | HEXAGON | 1 |

| 9 | Mold clamping machine | 300T | SHUNXING | 1 |

| 10 | Injection molding machine | 800T 190T |

HISION DONGHUA |

2 |